Do you want an innovative plasma cutting table drastically reducing your maintenance costs?

Slimcut plasma cutting table

SLIMCUT is a highly innovative plasma cutting machine. Based upon specific requests of our customers, it adequately meets the need to work continuously without compromising mechanical precision. In addition, SLIMCUT minimizes maintenance.

SLIMCUT is a plasma cutting machine serving the market of small companies seeking solve the thermal cutting issue autonomously and cost-effectively. However, despite its low price, SLIMCUT can be appreciated for both the quality of the product itself and of the final cut you obtain.

For these reasons, SLIMCUT is a highly technological product able to meet the requirements of the most demanding customers. SLIMCUT cuts in 1000×1000, 1500×1500 and 1000×2000 versions, but offers its best performance in the1500x3000 version, supporting up to 20 mm sheets.

In addition to plasma cutting, SLIMCUT may be used to cut plastic and wood, thus satisfying a wider range of cutters. Thanks to the accurate and in-depth study of such versatile cut, this plasma cutting table wins full and unreserved consensus of a wide range of cutters operating in various fields.

The project

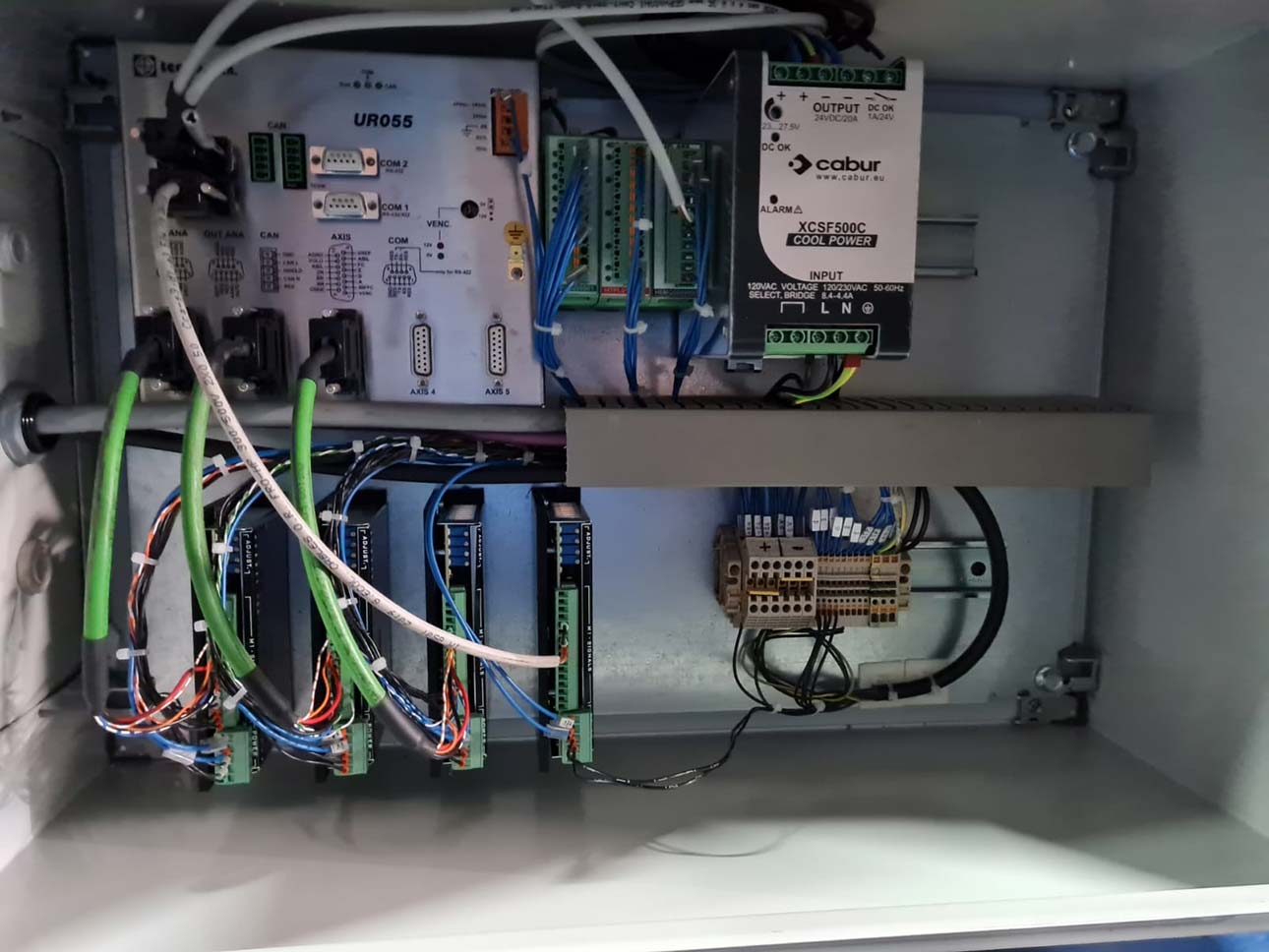

SLIMCUT by Plasma Plus is a plasma cutting machine consisting of a structure equipped with support tubes, it runs on linear guides with double circulation of spheres housed on rails (tracks).

The movement is transmitted by means of a rack and pinion coupling with backlash recovery and digital drives.

A special cable chain allows the connection between the moving machine and the ground equipment (electrical cabinet).

The motorization is 2-axis for machines less than one meter wide and 3-axis for machines one and a half meters wide. Brushless motors coupled to planetary gearboxes with reduced backlash are used for all axes.

The guides are recirculating ball with four rows. The software, very simple and intuitive, has 60 parametric figures inside and gives the possibility to import the drawings to be processed in “dxf” format and have nesting for sheet metal optimization

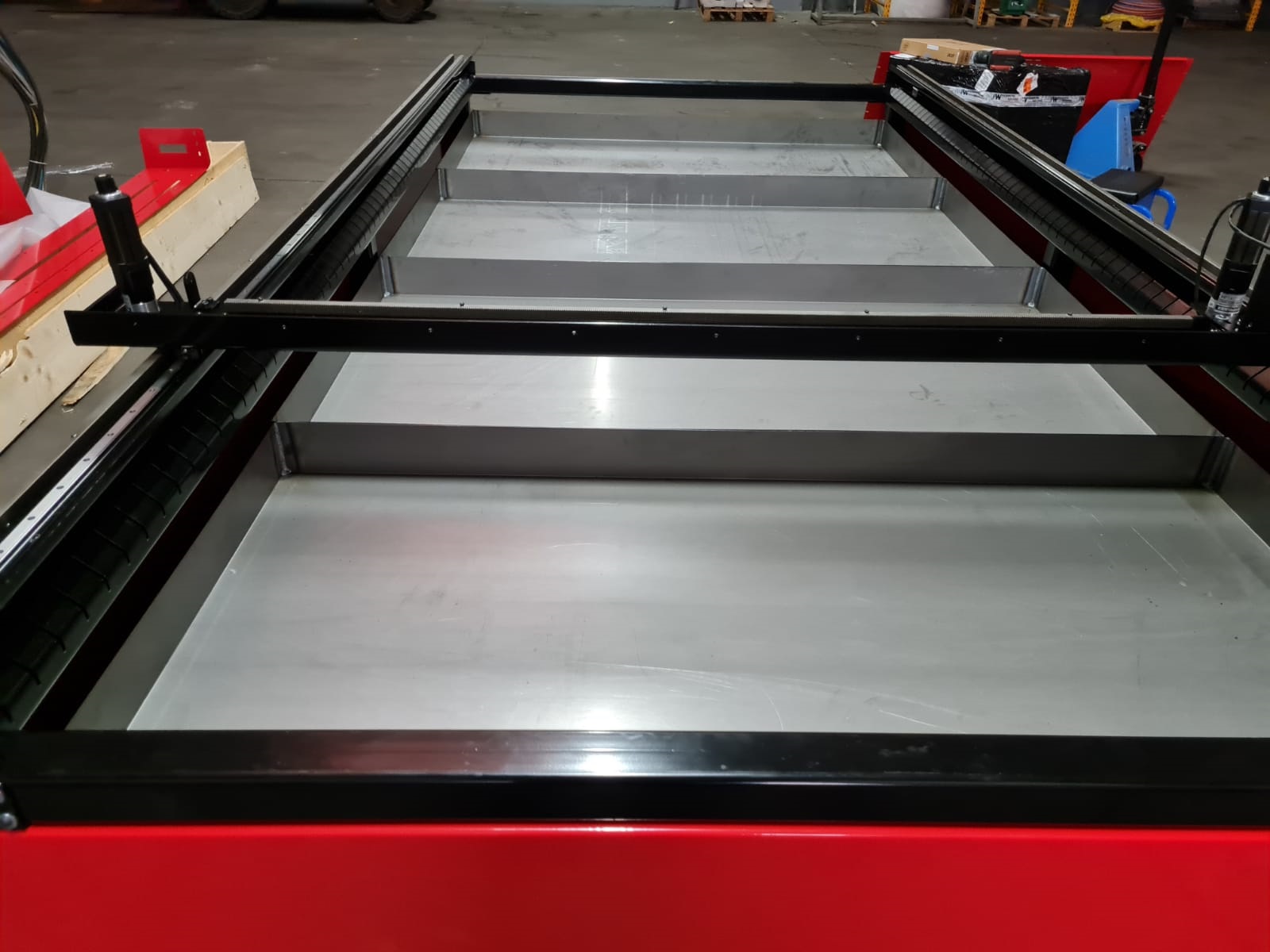

Stages of bench construction:

- Tubular assembly (photo 1)

- Assembly of linear guides and motors (photos 2, 3, 4)

- Assembly of the crosspiece and “z” axis (allows scrolling from top to bottom) (photo 5)

- Assembly on the machine and electrical cabinet (photo 6)

- Axis calibration and final testing

The plasma generator, supplied by us, is connected to the bench and that’s it: let’s start cutting!

1. SLIMCUT tubular assembly

2. Assembly of linear guides and motors

3. Assembly of linear guides and motors

4. Assembly of linear guides and motors

5. Assembly of the crosspiece and “z” axis (allows sliding from top to bottom)

6. Assembly of the machine edge and electrical cabinet

Technical features

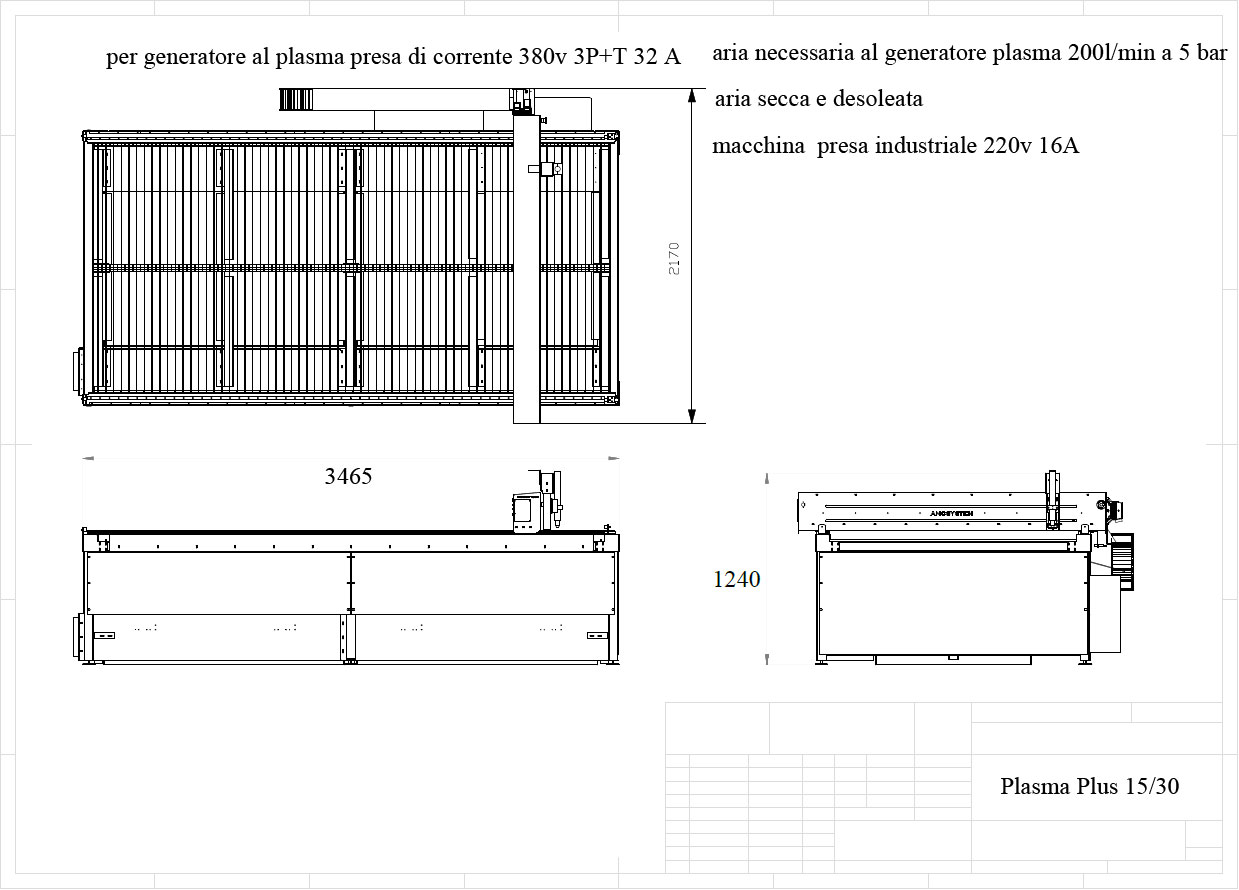

These below are the technical characteristics of the SLIMCUT plasma cutting machine, shown here to better explain every detail.

| DESCRIPTION | 1000*1000 | 1500*1500 | 1000*2000 | 1500*3000 | |

| Sheet size-max mm | 1000*1000 | 1500*1500 | 1000*2000 | 1500*3000 | |

| Thickness- max mm | 20 | 20 | 20 | 20 | |

| Motorization | Bruschless 2 mot | Bruschless Gantry | Bruschless Gantry | Bruschless Gantry | |

| Ground clearance | 800mm | 800mm | 800mm | 800mm | |

| Max interpolated speed | 26 m/min | 26 m/min | 26 m/min | 26 m/min | |

| Power supply | 220 VAc 1.5 A | 220 VAc 1.5 A | 220 VAc 1.5A | 220 VAc 1.5 A | |

| Precision | 0,3mm+/- | 0,3 mm+/- | 0,3 mm+/- | 0,3 mm +/- | |

| Computer | laptop | laptop | laptop | laptop | |

| Operating system | included | included | included | included | |

| DXF file import | yes | yes | tes | yes | |

| Parametrics | yes 60 pz. | yes 60 pz. | yes 60 pz. | yes 60 pz. | |

| Automatic torch height control | Included | Included | Included | Included | |

| Smoke filter | excluded | excluded | excluded | excluded | |

| Sheet metal support bench | included | Included | included | included | |

SLIMCUT in action

Examples of possible cuts performed with this CNC plasma cutting table.

Satisclients

We liked the wordplay but, as a matter of fact, we are talking about our most satisfied and loyal customers which, thanks to SLIMCUT, have optimized their production.

Ask now for a free quote for your SLIMCUT

Fill in the form and ask us any whatever you want to know. Otherwise, please call +39 333 7211994 and we will provide you with any clarifications you need.